Some Known Factual Statements About A1 Professional Asphalt & Sealing Llc

Some Known Factual Statements About A1 Professional Asphalt & Sealing Llc

Blog Article

Getting The A1 Professional Asphalt & Sealing Llc To Work

Table of ContentsWhat Does A1 Professional Asphalt & Sealing Llc Do?The Of A1 Professional Asphalt & Sealing LlcFascination About A1 Professional Asphalt & Sealing LlcGetting My A1 Professional Asphalt & Sealing Llc To WorkLittle Known Facts About A1 Professional Asphalt & Sealing Llc.

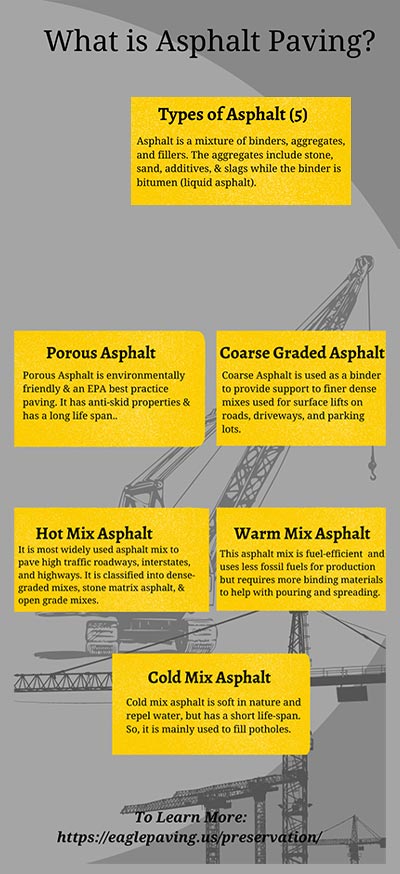

In its composition, asphalt is composed primarily of Bitumen combined with numerous kinds of accumulation, such as sand or gravel. Sidewalk, alternatively, is a type of concrete which contains aggregates, concrete, and water. what is cold asphalt?. Depending on the area and usage of the utilized pavement material, a blend of different chemical admixtures may be included in make it extra long lasting

What is the distinction in between asphalt and blacktop driveways? Blacktop is a mix of stone, sand, and crushed rock covered with asphalt. Blacktop is designed to create an even surface area because of its enhanced resistance to weathering and ability to birth larger tons. What is the distinction between asphalt concrete sidewalk and concrete? Pavement can be constructed from either asphalt or concrete, with asphalt being smoother and extra durable as a result of its binder, while concrete hardens through the healing procedure but often tends to use down with time because of weathering.

An Unbiased View of A1 Professional Asphalt & Sealing Llc

It is also much more lightweight and affordable. Exactly how do I preserve my asphalt driveway? One of the most fundamental part of preserving an asphalt driveway is making certain it's properly sealed. This shields the surface area of your driveway from harsh weather, salt, and various other harsh products. https://www.evernote.com/shard/s452/sh/55e605bb-a7ab-087f-2bbb-4cc3e94c5474/UvHUCPgKcZ18HESRJSnkIId24flOmNta2DAPD8UMVaYOk5-3NsYjse3oCA. You need to reseal the surface area every 2 or 3 years for ideal defense.

Asphalt and pavement are conventional components on roadways anywhere. Despite their resemblances, these 2 materials have some essential differences that make each suitable for different conditions.

Understanding these differences can help make certain an ideal decision is made when picking a surface area remedy. You can find out more articles similar to this one below.

The Basic Principles Of A1 Professional Asphalt & Sealing Llc

Lately, State highway firms and FHWA were amazed by a discovery: The private use re-refined engine oil bottoms in asphalt is prevalent. Simon Hesp, Queens University (Kingston, Ontario) Asphalt is the sticky black deposit that is left over from the handling of crude oil. It has actually been made use of in leading for even more than a hundred years.

The asphalt, which acts as the pavement's binder, is additionally one of the most costly component of the cost of the material for leading roads. The weight of an asphalt pavement differs depending upon the aggregate kind, the asphalt, and the air gap content. Using an average instance of 112 pounds per square backyard per inch of thickness, a 1-mile (1.6-kilometer)-long, four-lane highway with a 4-inch (10-centimeter) lift and 12-foot (3.6-meter)-wide lanes weighs about 6,300 bunches (5,700 statistics loads).

The 300 tons of asphalt in 2002 would certainly have set you back around $48,000. The rising cost of asphalt had a major influence on the cost of creating sidewalks, which raised interest in locating means to minimize costs.

Top Guidelines Of A1 Professional Asphalt & Sealing Llc

RAP already consists of asphalt, albeit aged material that does not have the exact same homes of fresh asphalt. During a corridor conversation at a 2010 technical meeting, Matt Mueller, after that a State engineer of products from Illinois, exposed that his division of transportation had located phosphorous in one of the asphalt binders it was purchasing.

The supplier rejected adding PPA, yet decreased to reveal what had actually been contributed to the binder. When pressed by the department of transportation, the vendor disclosed that it was adding what it called an asphalt extendernow known to be re-refined engine oil bottoms (REOB). REOB has a percentage of phosphorus, which is what division chemists initially identified.

"Nobody knew this product was being added to asphalt, had actually seen any type of research on how this could impact efficiency of hot-mix asphalt pavements, or understood for how much time and just how extensively it was being utilized throughout the country," claims Mueller. After conversations at the technical meeting, he claims, "It promptly went from being simply an issue in Illinois to ending up being a nationwide and worldwide problem." Part of the mission of the Chemistry Research Laboratory at TFHRC is to develop brand-new test approaches.

The buildings of asphalt binders differ widely depending on the source of the petroleum and the refining procedure made use of. For low wintertime Discover More temperature levels, softer asphalts are needed to avoid fracturing. To avoid rutting in warm climate, the asphalt must be stiffer. The original test for establishing the stiffness of asphalt was for the tester to chew it.

All About A1 Professional Asphalt & Sealing Llc

A maker called a dynamic shear rheometer (DSR) was presented to the market throughout the Strategic Freeway Research Program's study job, which ran from 1987 to 1992. The DSR is currently the sector requirement for measuring the viscoelastic properties of leading asphalt. However, the maker was not developed for the paving market.

The DSR allows product designers to develop toothpaste with the ideal consistency so that it can be pressed from a tube yet not fall off the toothbrush. The DSR tests binder positioned between 2 identical plates concerning the dimension of a quarter. Among home plates steps and the equipment determines the viscoelastic properties of the asphalt.

Report this page